FLEXIT – The high volume production line for Integrated Photonics

The Flexit project has been finalized in December 2023.

For an overview of the project: Download FLEXIT brochure

Background

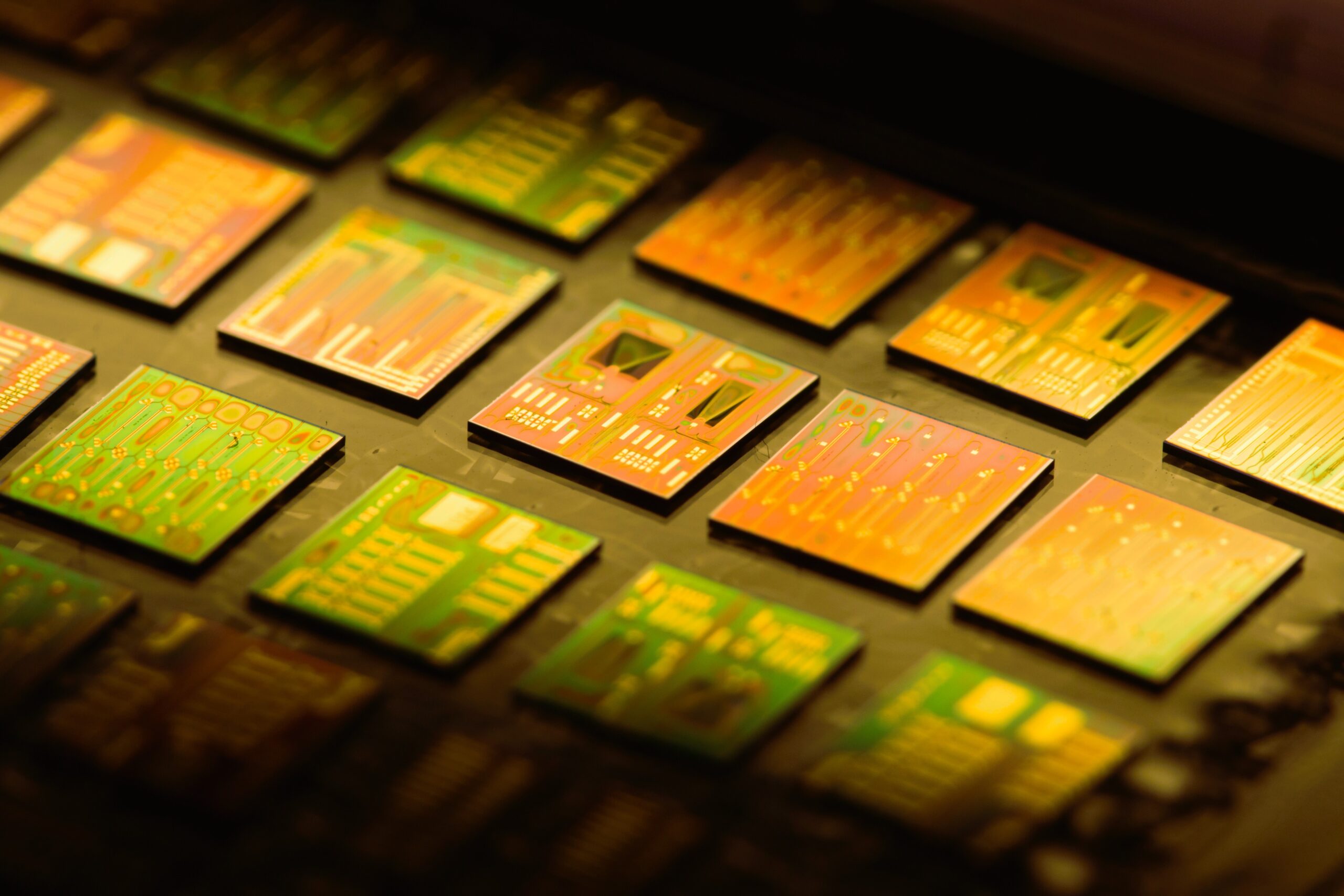

Photonic chips (PICs) strongly contribute to addressing several social issues in the areas of Health, Agro & Frood and Energy & Environment. In many electronic equipment sensors and controllers which can, for example, transport and analyze liquids and gasses, detect movement of objects and people (physical movement as well as inner body movements like heart beat, blood pressure and blood oxygen saturation) and send or receive sound signals. For these and many other applications, we can make use of photonic chips.

The relevance for PICs for modern electronic systems in healthcare i.e. manageable ultrasound equipment or breath and blood analyzers is great. More and more analyzing equipment shift from a laboratory environment to a manageable “Point-of-Care” equipment for a physician practice or consumer product equipment. Gas analyzing equipment based on PICs can be used as surveillance for the living environment of human and animal and in for example chemical production systems. Photonic engineering is not only applied in the high tech industry but also entering our day-to-day life.

The success of integrated photonics is partially because of the availability of efficient, advanced and flexible means of manufacturing. The FLEXIT project offers Dutch high tech companies the possibility to claim the new, not yet exploited (mined) market of assembly and integration machinery for volume production of photonic systems. In The Netherlands have a great and long history in the semiconductors business, there are excellent chances to unite forces and connect the Dutch semiconductor industry into the very promising Integrated Photonics ecosystem.

Project definition

There is a worldwide need for a next generation photonic chips and well organized and operating production chain (line) for photonic components, modules and systems. The industrial infrastructure is not yet optimal. This is mainly because of the absence of a generic solution for “assembly and packaging“ of photonic chips. Unlike the “assembly and packaging “of micro electronic chips, whereby connections are made via electronic conductors, the same activity for photonic chips is too complex. This means that assembly of photonic chips almost costs 4 times the cost of the chip itself pushing up prices and limit market penetration.

With the FLEXIT project our aim is on the assembly process to connect In PIC’s using a news self aligning concept. This technology is very promising and, as far as we know, has never been realized elsewhere. The FLEXIT consortium considers this technology as the missing link in the cost-effective integration and packaging of microelectronic photonic modules. By reducing the cost of assembly with the use of a combined flexible assembly technique and product self-alignment this eventually will considerably reduce the end product cost-price resulting in a faster adoption by the market. This break-through will show the world how valuable and strong the Dutch semiconductor and PIC ecosystems are.

FLEXIT aims to streamline the manufacturing chain and apply crucial improvements. The manufacturing chain applies to different companies, each with individual processes: design, front-end processing, back-end assembly, packaging, testing and data management. Step by step the manufacturing chain is being improved and expanded with new developed and improved tools, including manufacturing processes, through which the manufacturing yield rises (times >10), costs are drastically reduced (-50%) and delivery reliability is maintained (>95%).

Through FLEXIT these processes will seamlessly connect into each other. Next to that it creates a full supply chain for mass production of photonic components. The Netherlands can become the international production center of high-volume photonic manufacturing equipment and fulfil the enormous global demand. The project scope makes it possible that these developments also find their way to the Dutch SMEs.

Project organization

The project team members are selected on actors-in-the-chain approach. All members are well-know to each other and bring lot’s of experience in their specific area. The FLEXIT-project team exists of 11 partners with different backgrounds. No less than 8 companies are entitled as a SMB company, 1 has a large industry entity, finally a research organization and a community party from the high tech sector are involved. Together they cover the whole area of integrated photonics including the opto electronics system and machinery companies, from research to commercial delivery. Most of them are situated in the east of The Netherlands, two of them in southern region.

The development of this breakthrough FLEXIT project demands expertise in the area of design, materials, production and characterization of integrated photonic and electronic equipment and switches, chip assembly and packaging technology and of course, the specific scope areas for which demonstration equipment will be made. Partners cover the whole value chain of PIC-production, from knowledge and ideas to photonic applications.

Download FLEXIT brochure

Partners

|

LioniX International > Develops and commercializes on siliciumnitride (SiN) based waveguide technology (TriPlex) for a variety of applications and is leading in the photonic sector. |

||

| SMART Photonics > The first “pure play Foundry” in the area of InP PIC production and on the verge of scale up.

|

||

| ItoM > Development & design of CMOS semiconductor IC’s for the high tech industry in which CMOS foundries are hired for production and ItoM takes care of implementation and testing.

|

||

| Synopsys > Development and delivery of design software and tools for the development of photonic IC’s, based on several substrates like InP, SiN, Silicon Photonics and future polymers.

|

||

| Chilas > Development and production of semiconductor lasers based on several materials with high power in combination with integrated technology.

|

||

| Workfloor > Supplier of factory data collection systems.

|

||

| PHIX > World leading packaging and assembly foundry for Photonic Integrated Circuits (PICs), building optoelectronic modules based on all major PIC technology platforms in scalable manufacturing volumes.

|

||

| Salland Engineering > Worldwide leading in Test Technology & Engineering specialised in solutions and services to improve efficiency and quality testing at semiconductor manufacturers.

|

||

| IMS > Development of production and assembly lines for hybrid microsystems with added value like lenses for smart phones, medical implants and micro systems.

|

||

| Berenschot > A consultancy company that supports High Tech NL with grant proposal writing, project management, and facilitates cooperation between companies and growth of ecosystems.

|

||

| High Tech NL > A nationwide community organisation for the high tech equipment industry and focussed on semiconductor front- and back-end equipment as also applied markets like Health Care, Agrifood, Automotive and Telecom. |

A series of leaflets on project partners are available:

230502-SMART-Photonics-partner-in-FLEXIT

230621-LioniX-International-partner-in-FLEXIT

230630-Salland-Engineering-partner-in-FLEXIT

230724-Chilas-partner-in-FLEXIT